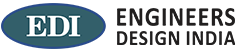

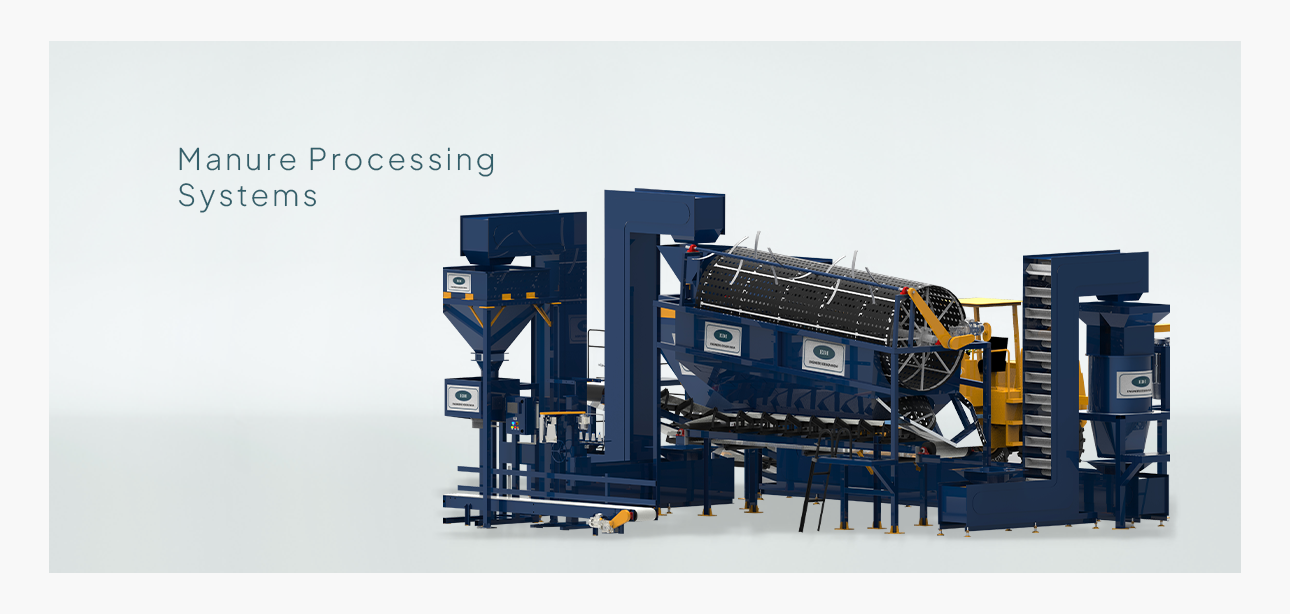

Trommel/Rotary Screens

We are manufacturing and supplying a qualitative assortment of Manure Processing Systems for all type of manures. Designed and manufactured with utmost precision.Compost or Bio Organic Manure fertilizers derived from various decomposable organic materials are widely used as fertilizers as an alternative to chemical fertilizers. These organic fertilizers are dried in open fields to maintain moisture content ranging between 30-40% before packing and then processed to required particle size before packing.

Scope of Supply

Ground Hopper

Conveyor/Bucket Elevator

Crusher Unit

Trommel Unit

Feed Hoppers

Feed Hoppers

Bagging Machine

Belt Conveyor

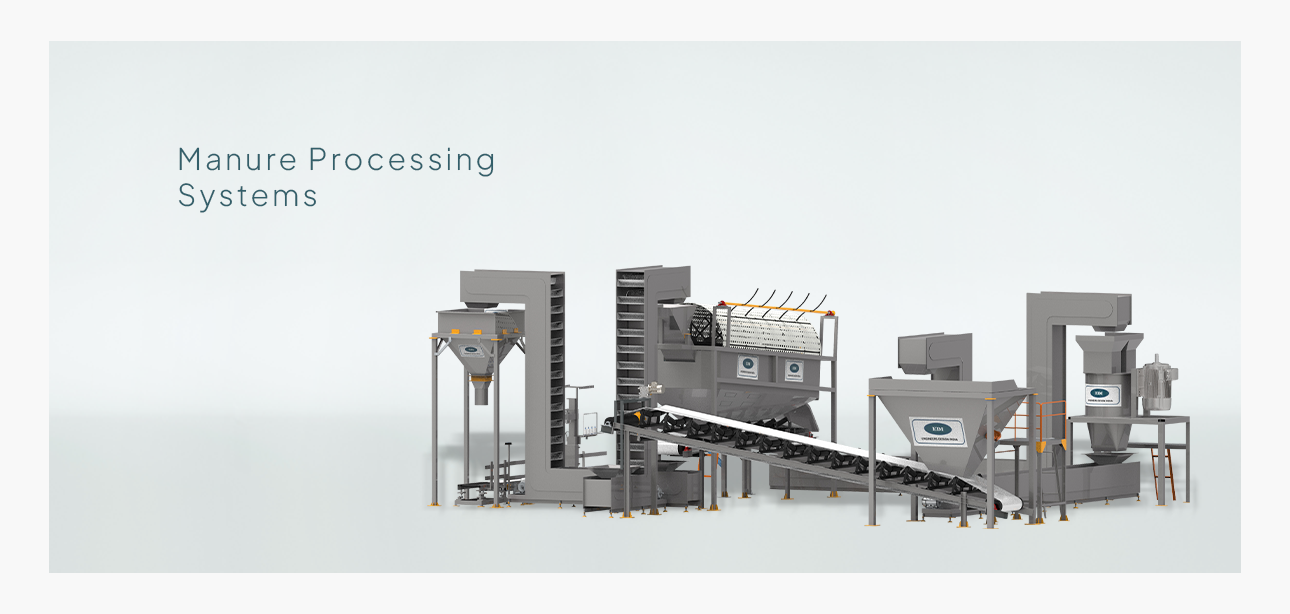

Additional Scope. Truck Loader; Conveyors

Ground Hopper

The manure duly collected from open dry fields, by payloaders, is dumped into Ground hoppers from where it is conveyed to suitable crushers.

Conveyor/Bucket Elevator

The conveyors to convey such material can be selected as Bucket elevators, Trough belt conveyors, or cleated belt conveyors. Bucket Elevators and Conveyors designed and manufactured by EDI are sturdy and well equipped to handle the production.

Crusher

Raw material is very uneven in sizes. The purpose of the EDI crusher is to provide the uniformity of the material. The output size varies depending on the material. The crushed material to suitable size from these crushers are then conveyed to Rotary Screens.

Trommel

EDI Trommel is designed where required particle size material is screened and conveyed to Bagging (Packing) Hoppers. The oversized material is again fed to crushers for further crushing.

It consists of a perforated cylindrical drum that is normally elevated at an angle at the feed end. It is used to help separate and classify out the material for further processing.

Feed Hopper

The Bagging hoppers equipped with suitable agitators (vibratory motors, Churners), to maintain the flowability of the powdered fertilizer, are positioned above the Automatic Bagging Machines.

Automatic Bagging Machines

EDI Bagging Machines then pack the fertilizer in open mouth bags with required weighment size. The weighment size of the filling bags can be set by the operators. Bag Placing done manually, rest all operations are fully automatics.

Conveyors & Stitching

The bags duly filled with required weight fertilizer is then conveyed and stitched by the column mounted heavy duty stitching machine and moved ahead by conveyor for stacking in warehouses or loading into vehicles for transportation.

Bag Tilter & Truner

The bags duly filled with required weight fertilizer is then conveyed and stitched by the column mounted heavy duty stitching machine and moved ahead by conveyor for stacking in warehouses or loading into vehicles for transportation.

Truck loader

EDI Truck loader can be easily movable in the warehouse. It collects the bag from the preceding conveyors or can be placed manually. It helps in minimising the use of labor, and provide efficient results. With Height adjustable booms, the bags can be stacked easily.